What it takes to make the cleanest LandCruiser BJ60, that nearly went for scrap

Member Spotlight

Copper from Rust: Resurrecting a BJ60 Trail Rig

Pete’s 1984 Land Cruiser BJ60 Resurrection

In the heart of logging country in northern New Brunswick, there’s a garage where the sparks fly, the beers are cold, and one man’s passion for rebuilding cars from the ground up is on full display. Pete—a former parts manager, weekend bodyman, and full-blown Land Cruiser addict who turned a rusted-out 1983 Toyota BJ60 into a custom-built masterpiece, 13 years in the making.

Cutting, Welding, Rebuilding

The BJ60 was far from roadworthy. Rust had eaten through the floors, panels were shot, and nearly everything needed work. Luckily, a pair of rust-free rear doors came with the truck. That small win helped kickstart a full-scale restoration.

After stripping the LC down, it was apparent that there was a good battle happening between the rust and the metal, and it looked as though the rust was winning. It was difficult to find a spot to weld to, and soon the custom cross bracing would be the only thing to keep the build together. "You can only take so much out before you start to put some back in." I fairly confident guarantee it will not rot through again in his lifetime, Pete went with 16 gauge sheet metal, 1/8 inch tubing and diamond plate flooring.

Not one section of the build was spared from the welder. Rad support, frame, rockers, doors, floors, if it was metal it likely got touched by the welder. Once it started to look like a vehicle again, everything got primed. The customization was about to begin.

Custom Everything: A Builder’s Touch

Do you know what you can customize with a Lincoln Electric 140c welder and JD Squared Model 52 tube bender? Pretty much anything you want. This is when the project really escalated from a rust bucket to a one-of-a-kind off-road rig, Pete’s BJ60 reflects a builder’s mind at work. It’s not just about restoring—it’s about reimagining. Some of the standout features include:

Custom Front & Rear Bumpers

Custom Inner Fenders

Custom Outer Fenders

Custom Extended Rear Seating Area by 2 inches (had to do this twice)

Custom Dog Legs (had to do this twice)

Custome Roof-Mounted Light Bar

Custom Battery Box Relocation

Custom shock mounts

Custom side steps

Custom undercarriage protection

What's under the hood?

The legendary 2H diesel engine is a workhorse known for durability and low-end grunt — a perfect fit for overland adventures and trail crawling alike.

Engine: 2H 4.0L Inline-6 Diesel

Output: 107 hp @ 3,500 rpm

Torque: 177 lb-ft @ 2,000 rpm

It's whats inside that counts

The interior was covered in Dyanmat and EZ Cool High Performance Insulation to control heat and noise, and black vinyl flooring to cover it all up. The Corbeau seats were a great fit with upgraded seatbelts from seatbeltplanet.com. One of the coolest upgrades to this build was lengthening the rear seating area by 2 inches, all for comfort of the passengers. This would prove to throw Pete a curveball when attempting to bolt in the fold down rear seat. "My planning for the rear seat in this thing, mock up was done without seat foams ! A Big NO NO !!"

That wasn't the only issue though. "When I did my rear dog legs I had not fitted WITH the door seals."

In disbelief that he would need to cut up the floor and dog legs, it's how things go sometimes in these builds. "They say we learn the most out of our screw ups, eh."

What’s Next for the Build?

While Pete considers the build “90% done,” it is now running, driving, and is become more reliable. There are still a few things on his wish list. A front coil conversion, air lockers, and a turbo are high on the priority list. An OM606 diesel engine swap has also crossed his mind, along with a Tundra brake upgrade to handle the extra power.

“Time, money, and knowledge—that’s what slows you down,” he says. “But I’m still going.”

Would He Sell It?

Pete has been offered $100,000 for the truck. And he seriously thought about the offer. Briefly.

“It would be cool to say I built and sold it for that price,” he admits. “But she’s still here. So I guess that answers that.”

Are you working on a project like this?

Share your project with the community, add it to the map, and you could be on the next Member Spotlight.

More Spotlight Builds

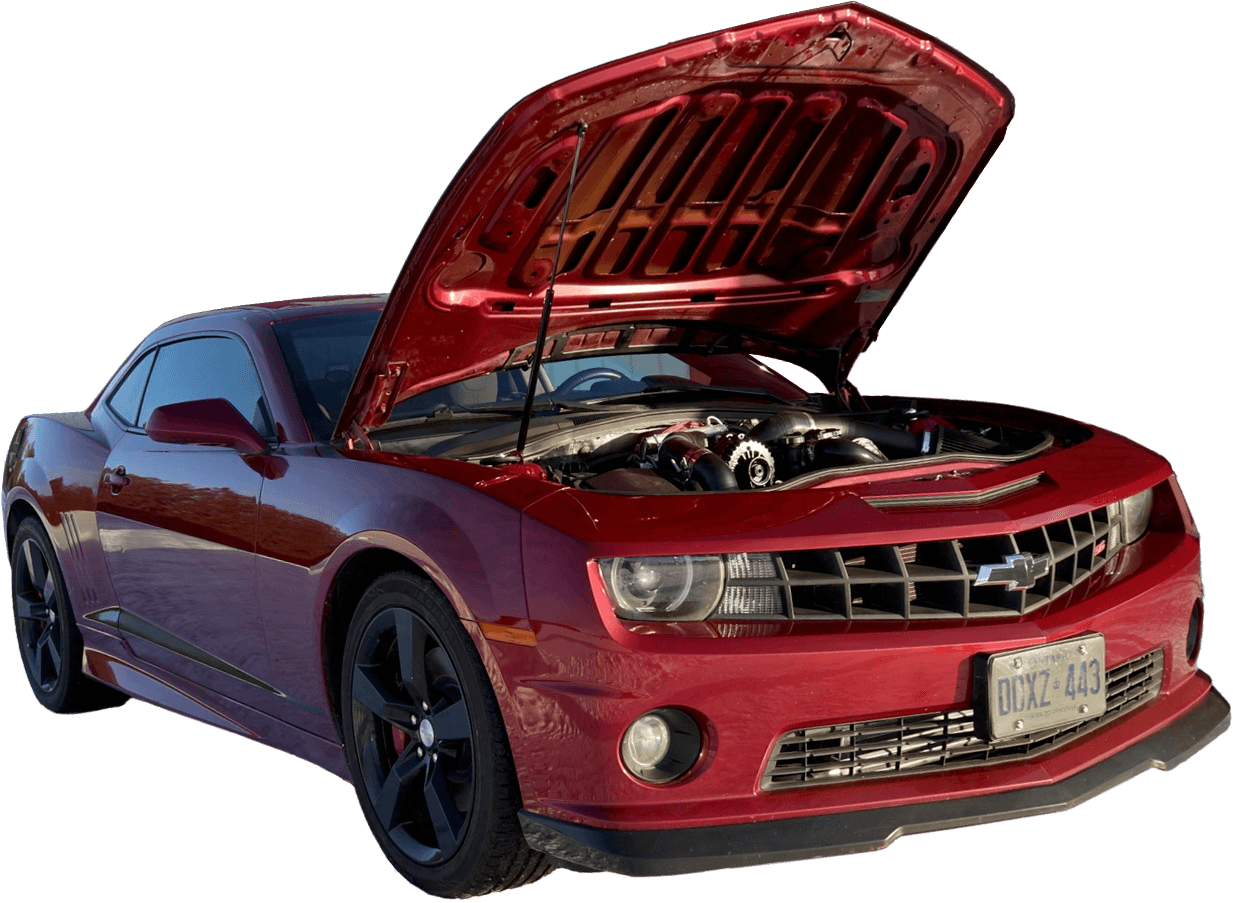

The Coalmaro SS - a Duramax swapped Camaro

LS V8 in a Subaru WRX: Big Power, Tight Fit

LeMans Long Roof: A Belgian Phantom with American Muscle Roots

Cocaine and High Revs

Intakes and Keepsakes: Reviving a Family Camaro with Heart

Transform Your S10 into a V8 Off-Road Beast

This Abandoned Stock Car is a LEGENDARY CHAMPION

R2.8 Diesel Swap: Transform Your 4Runner for Overlanding

From Auction Find to Custom 4x4 Semi

Built to Haul: 24 Valves, 13 Gears, One Legend